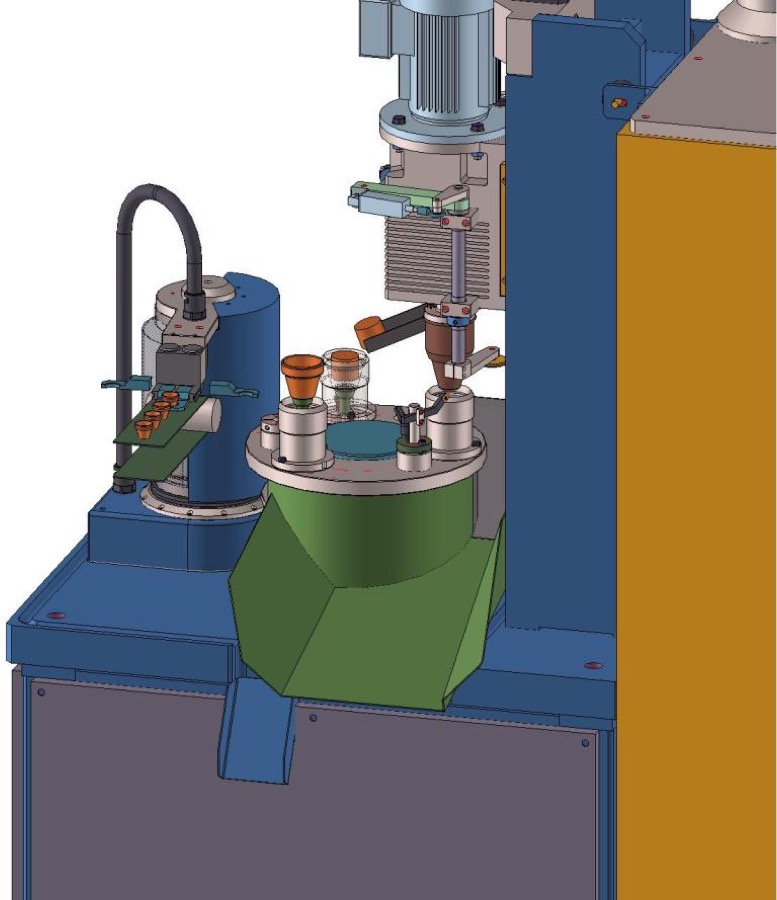

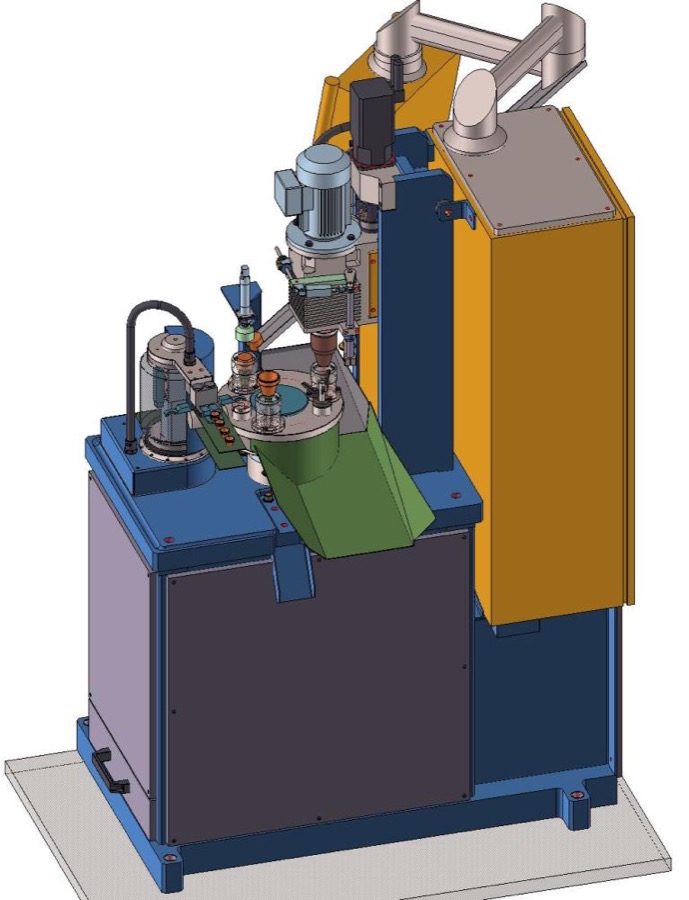

Pressing of round an irregular products using steel moulds, CNC adjustable, efficient change overs and settings. For products with diameters from 50 up to 570 mm. Production up to 3000 pieces per hour.

CNC 3 press

SUPER FAST ø < 50 MM

CNC 3 PRESS

Extremely fast (3000H) pressing

machine, with products diameter

sizes up to 50 mm.

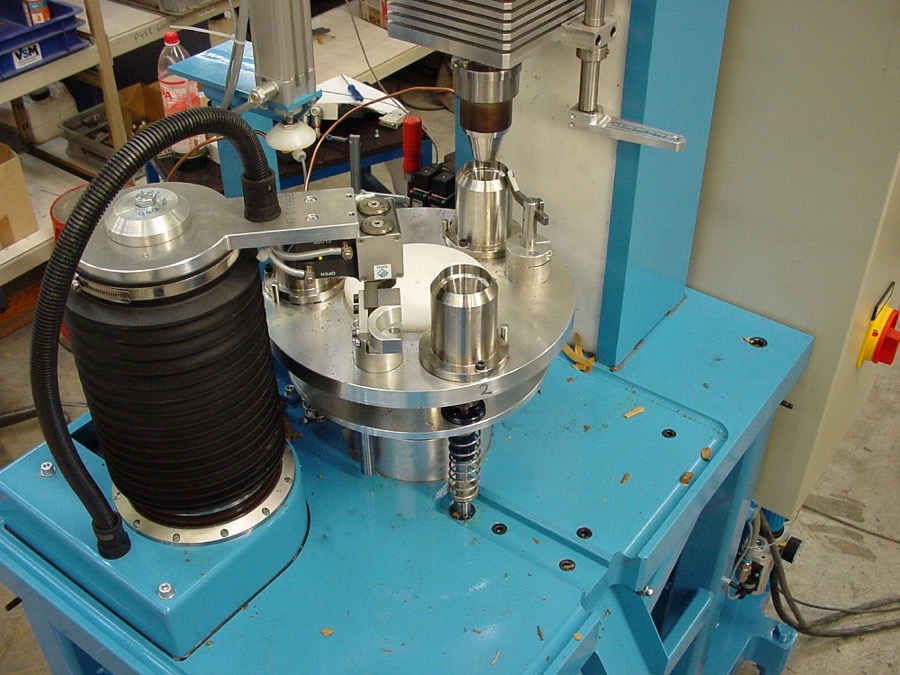

CNC 3 PRESS

The CNC 3 press series is designed for high speed producing ceramic products with steel moulds and the use of releasing agent oil. With this press a very high product standard can be achieved: all products are identical, smooth and exactly round, have a constant wall thickness and a perfect finish. The machine includes: a pressing unit with upper and 3 lower moulds, 2 vacuum-heads to pick up and finish the pressed pot or with pliers take out of the product, and special CNC-Control unit. Options are: various clay feeding units, product transportation systems, finishing and decorating devices, etc. Its extreme high capacity combined with high quality output, is achieved by up to 5 servo drives. The CNC Control allows for a quick change over and settings in production. The press is of robust build, well finished, and all linear ways are perfectly covered and sealed from clay and pressing agent oil. The press is supplied with an automated lubrication unit. The machine has an outstanding well design and well-considered configuration of machine components. With all this a very long life span is achieved. The modular construction makes the press easy to fit in all production lines.

ADVANTAGES

- Available in 2 options XO and X normal production execution; both in high or normal production execution;

- Flexible production for round and non-round products;

- No plaster moulds anymore, but steel long life span moulds (up to 1.000.000 pcs);

- High quality finished products in one go;

- High daily output due quick motions and production surveillance software;

- Possible to automatically reshape or make imprints after production. (many options);

- Energy saving production machine;

- Faster set ups and quick change over’s with CNC-XO-Control, with touch screen;

- Suitable to fit in any production line because of small modular designs;

- Long life span and little planned maintenance required;

- Internet connection to VSM for monitoring;

- Clear list of warnings plus feedback on machine status to operator in case of problems or machine failure;

- Turn key delivery;

- Excellent after-sales service and training;

- Many favourable references from customers;

- Safety according European standards (CE mark);

- State- of the art safety PLC for quick and safe starting the machine after a standstill.